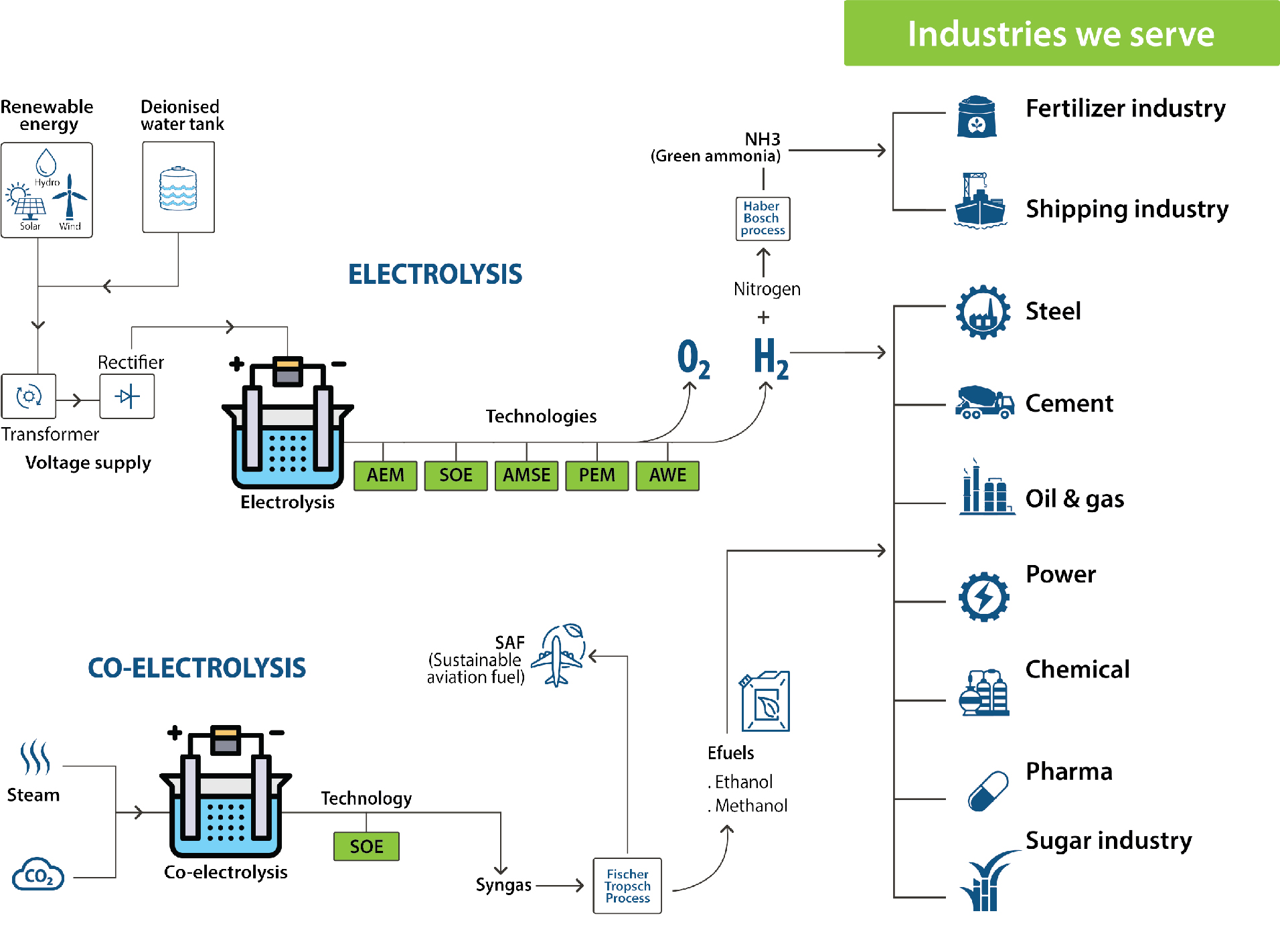

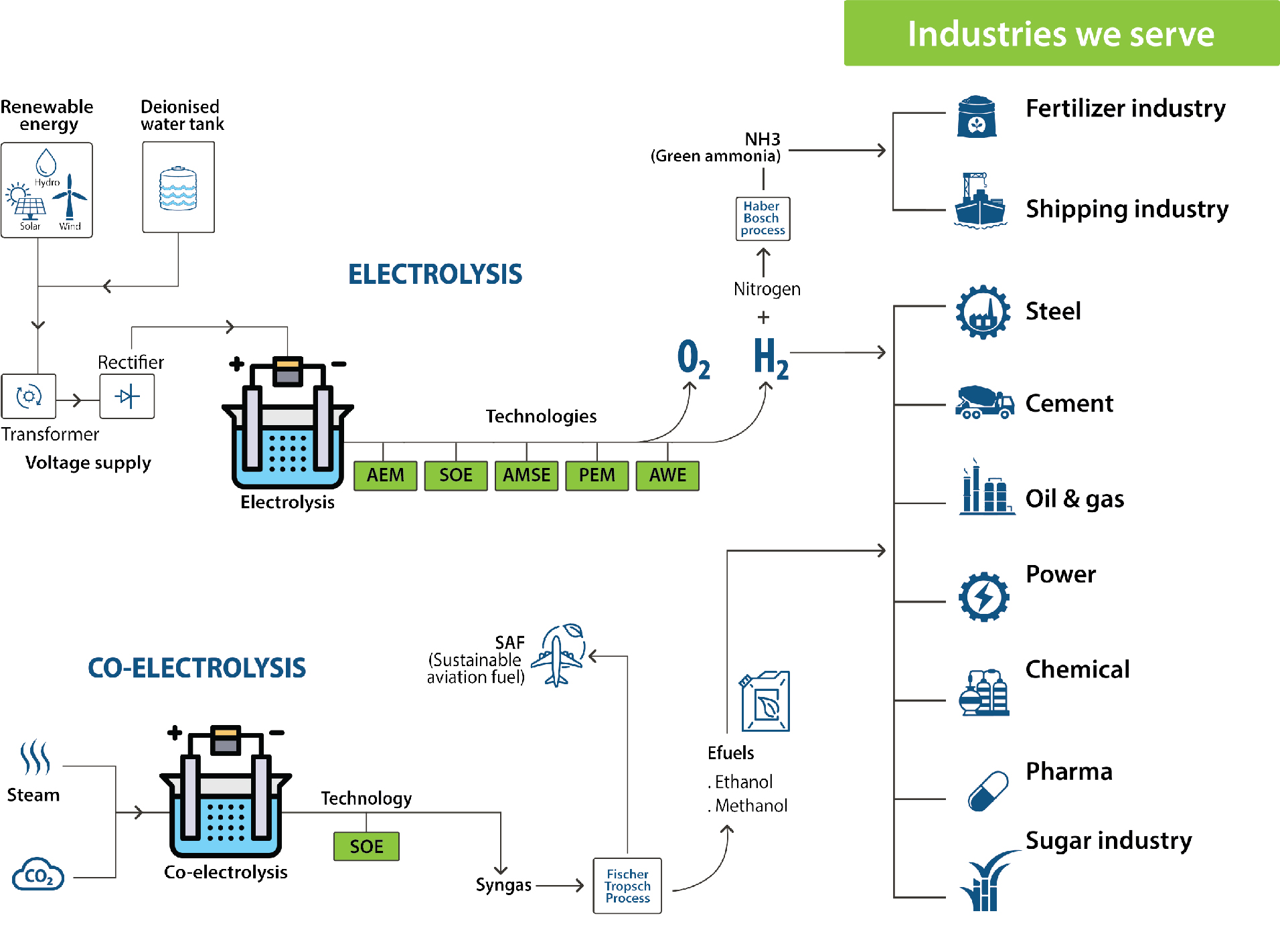

How it works

| Technologies | ||||||

|---|---|---|---|---|---|---|

| Sr.No. | Characteristics | AEM Anion Exchange Membrane |

SOE Solid Oxide Electrolyser |

AMSE Alkaline Membrane Solid Electrolyser |

PEM Polymer Exchange Membrane |

AWE Alkaline Water Electrolyser |

| 1 | Electrolyte | Anion Exchange Membrane |

YSZ | 15% KOH | Proton Exchange Membrane |

20-30% KOH |

| 2 | Temperature range | 60-70 C | 700-800 C | 60-70 C | 60-70 C | 60-80 C |

| 3 | Typical discharge H2 pressure | 30-35 bar | 1 bar | 30 bar | 30-40 bar | 16-30 bar |

| 4 | Current density | 1.2-1.5 A/cm2 | 0.5-1 A/cm2 | 0.8 A/cm2 | 2.4-3.0 A/cm2 | 0.2-0.5 A/cm2 |

| 5 | Demonstrated durability | 35,000 hrs | 50,000 hrs | N.A. | 80,000 hrs | 80,000 hrs |

| 6 | Typical current efficiency | 50-70% | 80-85% | upto 65% | 50-65% | 50-70% |

| 7 | Specific energy consumption | 48-53 kWh/kgH2 | 37-40 kWh/kgH2 | 52-54 kWh/kgH2 | 50-53 kWh/kgH2 | 52-57 kWh/kgH2 |

We manufacture affordable, reliable & efficient electrolysers from KW to MW scale

AEM is an emerging technology that combines the benefits of both the PEM and AWE technologies sans the usage of precious metals thereby making the stacks...

The Solid Oxide electrolyser is one of the most efficient electrolysers amongst the electrolyser portfolio and is capable of co-Electrolysis with...

Alkaline Membrane Solid Electrolyser technology is the most innovative and still relatively unknown. The basic principle and process scheme are the same as...

Pure water is fed into the anode of the electrolyzer, where it is split by a catalyst. Oxygen is produced directly on the anode side, whereas the...

Alkaline Water Electrolyser (AWE) has two electrocatalytically active electrodes immersed in a liquid alkaline electrolyte (NaOH/KOH) solution, separated by...

| Technologies | ||||||

|---|---|---|---|---|---|---|

| Sr.No. | Characteristics | AEM Anion Exchange Membrane |

SOE Solid Oxide Electrolyser |

AMSE Alkaline Membrane Solid Electrolyser |

PEM Polymer Exchange Membrane |

AWE Alkaline Water Electrolyser |

| 1 | Electrolyte | Anion Exchange Membrane |

YSZ | Proton Exchange Membrane |

20-30% KOH | |

| 2 | Temperature range | 60-70 C | 700-800 C | 60-70 C | 60-80 C | |

| 3 | Demonstrated durability (Operating hrs) |

40,000-50,000 | 40,000-60,000 | 60,000-80,000 | 35,000 | |

| 4 | Demineralised water consumption - expected [1/kg hydrogen] |

10 | 11 | 12 | 11 | |

| 5 | Modularity KW | Up to 1000 | Up to MW | Up to 5000 | Up to 5000 | |

Copyright@2024 | homiHydrogen Private Limited